At Techworx we pride ourselves by utilising the latest state of the art Computer Aided Design software. Whether you are a designer looking for a new protype part to be designed/made or a blue chip company looking to outsource all of its fabricated components, we have the infrastructure to support your needs.

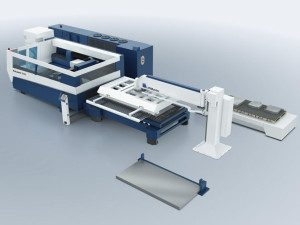

Techworx has grown its product knowledge over the years to become one of the midlands fastest growing complete laser manufacturing Cells using the latest state-of-the-art machines producing precision components, on time everytime. Laser cutting is one of the fastest growing precision engineering processes

Complete in house press braking Cell running the latest press brakes. Catering up to 3M forming full cnc 7 axis. Quick change tooling eliminates long changeover times reducing bending costs.Parts are now completed in one rotation utilising 7 axis programming.

Fundamentally our main area of expertise are Laser Cutting and Forming of flat sheet components but we also offer our fabrication cell to our customers for all tooling, drilling, jigging, welding, Studding, and inserting. Let us see how we can help you.

Techworx Installed their paint plant facilities back in 2013 due to continued problems outsourcing painted products with regards to quality issues and turnaround. We can now offer wet spray and powder coated products to finish your components that are Lasercut and formed in house all under one roof

Techworx was established in 2006 to provide a first-class customer focused sub-contract laser and fabrication service throughout the EU.

Techworx

News

February 2015

IS0 14001 Accreditation achieved

December 2014

ISO9001 Accreditation achieved

September 2014

Trumpf 2525 Flatbed Laser inc Liftmaster installed for scratch free Clean Cutting of Stainless and Aluminium sheet

February 2014

Trumpf Trubend 3120 7 Axis Pressbrake installed to add to our bending capabilities

February 2013

New Finishing Paint Shop installed to complement all other operations that we cater for. We can now offer Wet / Powder Spray painting of work to finish ready for delivery to customers all under one roof

August 2012

Trumpf Trulaser 3030 Flat bed laser installed to increase our cutting capacity up to 25mm Mild Steel to cater for heavy goods sectors